How 3D Scanned Models Are Used

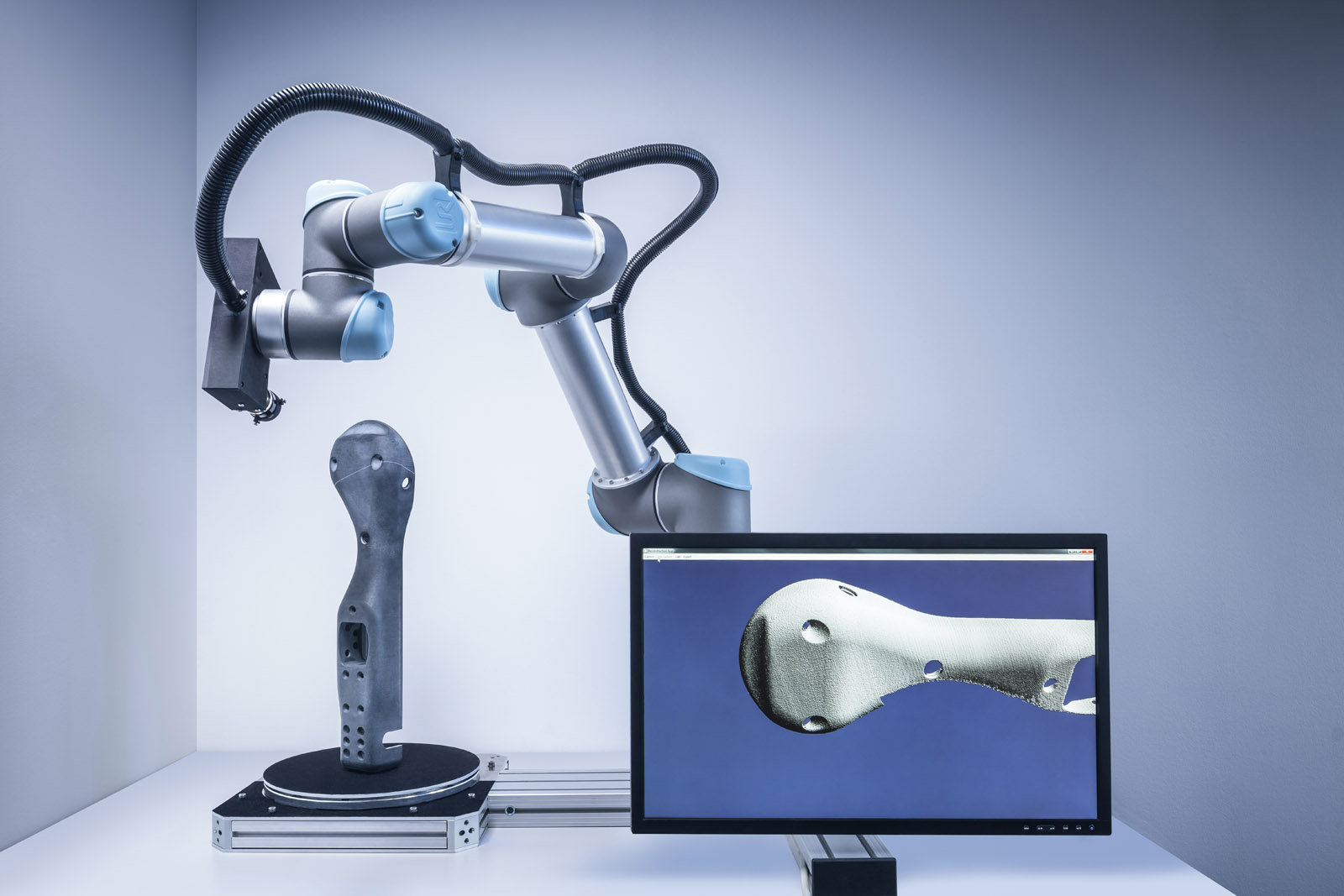

A 3D scanned model is more than a visual replica of a physical object. It is a precise digital representation built from real world measurement data. Every surface, curve, and feature reflects the actual geometry of the object, not an assumption or approximation. This makes the data reliable and usable across engineering and manufacturing workflows.

You use a 3D scanned model to design new parts, analyze existing components, inspect accuracy, modify geometry, and manufacture replacements. Unlike manual measurement or traditional modeling, 3D scanning captures complex shapes, freeform surfaces, and fine details in a short time. The result is data you can trust for critical decisions.

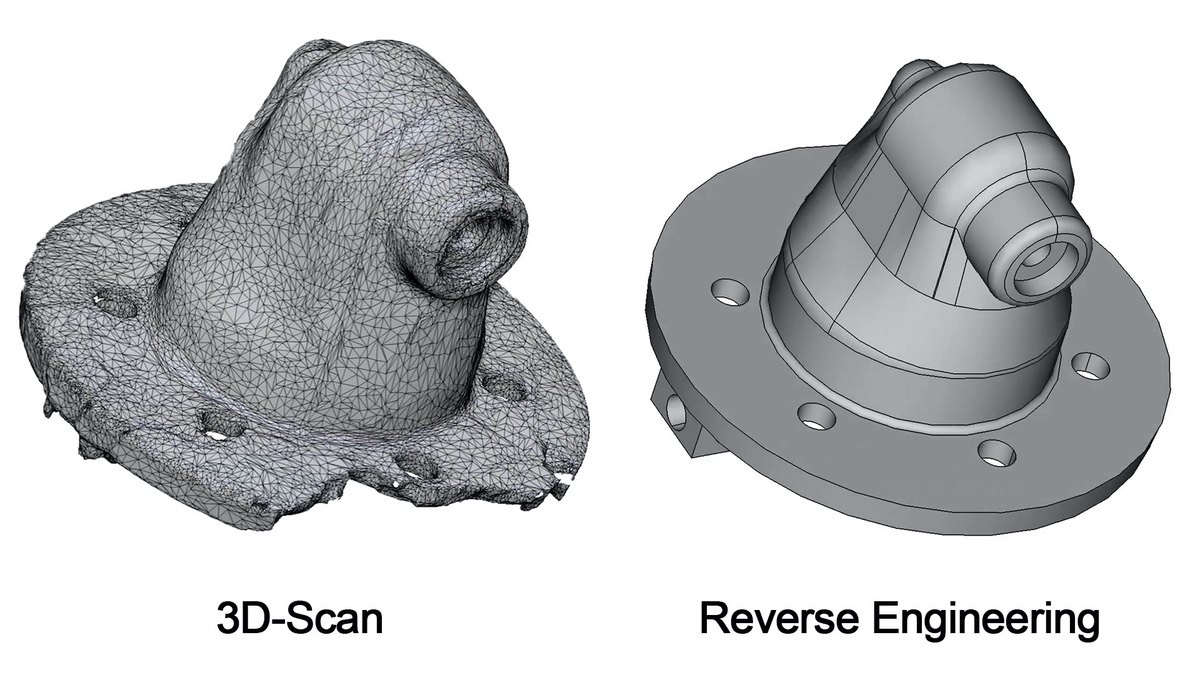

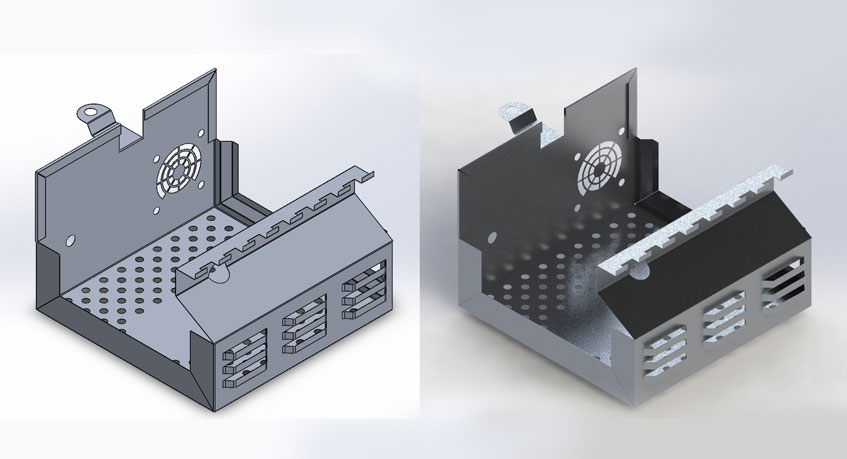

Reverse engineering and CAD reconstruction

You use a 3D scanned model to recreate missing or outdated CAD data when original design files are unavailable or incomplete. This is common for legacy parts, custom tools, molds, and imported components that were never delivered with technical drawings. In many cases, the physical part is the only reference available.Engineers convert the scanned geometry into clean, editable CAD surfaces that match the real part accurately.

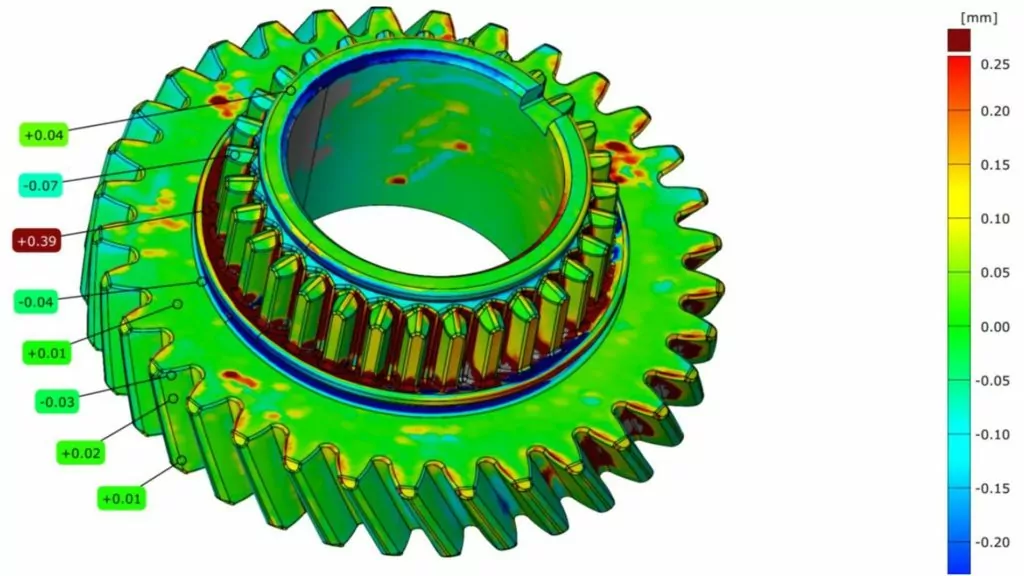

Quality inspection and deviation analysis

A scanned model compares directly with the original CAD design to verify dimensional accuracy. Specialized inspection software highlights deviations using color maps, making it easy to see where the part differs from the nominal geometry. Even small variations that are difficult to detect with manual tools become clearly visible.This process helps detect warping, surface wear, shrinkage, and dimensional errors at an early stage.

Design modification and optimization

You modify real world geometry instead of working from ideal or estimated shapes. Engineers rely on scanned data that reflects how the part actually exists, including variations caused by manufacturing or wear. This removes guesswork from the design process.Using this data, engineers adjust wall thickness, tolerances, mounting features, and interfaces with confidence. Changes are based on measurable geometry, not assumptions.

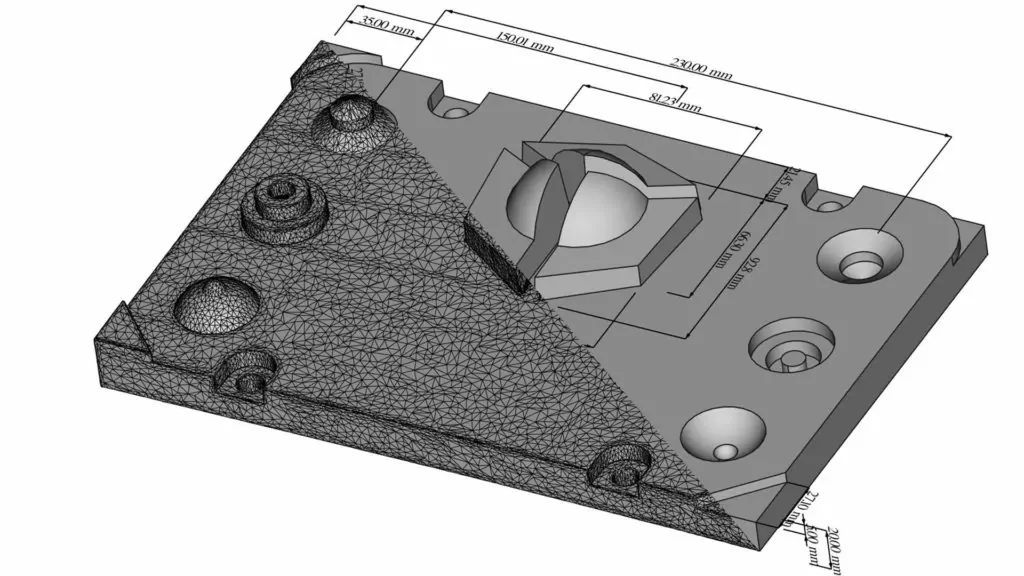

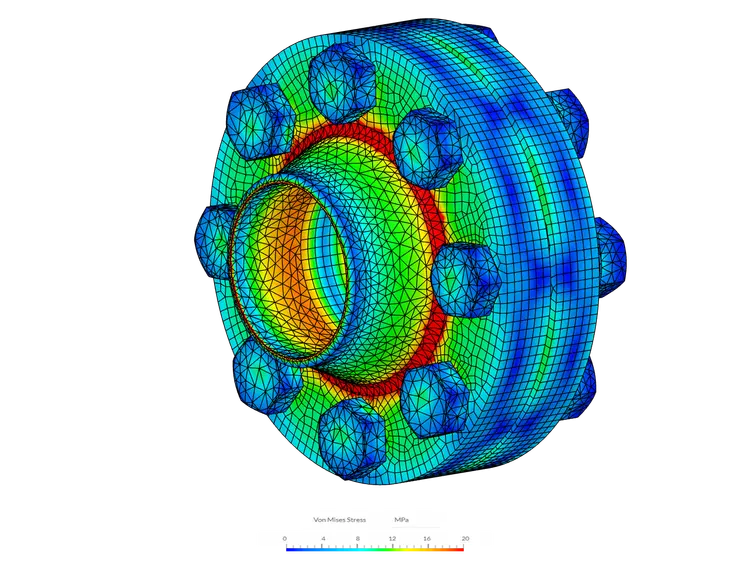

Simulation and engineering analysis

You use scanned geometry for structural, thermal, and flow simulations when accuracy is critical. The scanned model represents the true shape of the part, including small features and surface variations that are often removed or simplified in traditional CAD models. This leads to simulation inputs that better reflect real world conditions.As a result, analysis outputs become more reliable for predicting stress distribution, heat transfer, and fluid behavior.

A 3D scanned model becomes a central data asset. It connects the physical and digital worlds. When used correctly, it improves accuracy, speed, and decision making across the entire product lifecycle.