How to Design for Additive Manufacturing

Design for Additive Manufacturing, DfAM, is the practice of designing parts specifically for 3D printing rather than adapting traditional manufacturing designs after the design is complete. It starts by considering how the part will be built layer by layer, how material behaves during printing, and how geometry influences strength and accuracy. This shift in mindset is essential for achieving reliable and repeatable results.

Instead of forcing conventional design rules onto additive processes, DfAM uses the strengths of additive manufacturing from the beginning. Engineers take advantage of geometric freedom, internal features, and optimized material placement. This approach allows the creation of parts that are lighter, stronger, and more functional while reducing material waste, minimizing post processing, and eliminating unnecessary assembly steps.

What DfAM (Design for Additive Manufacturing) really means?

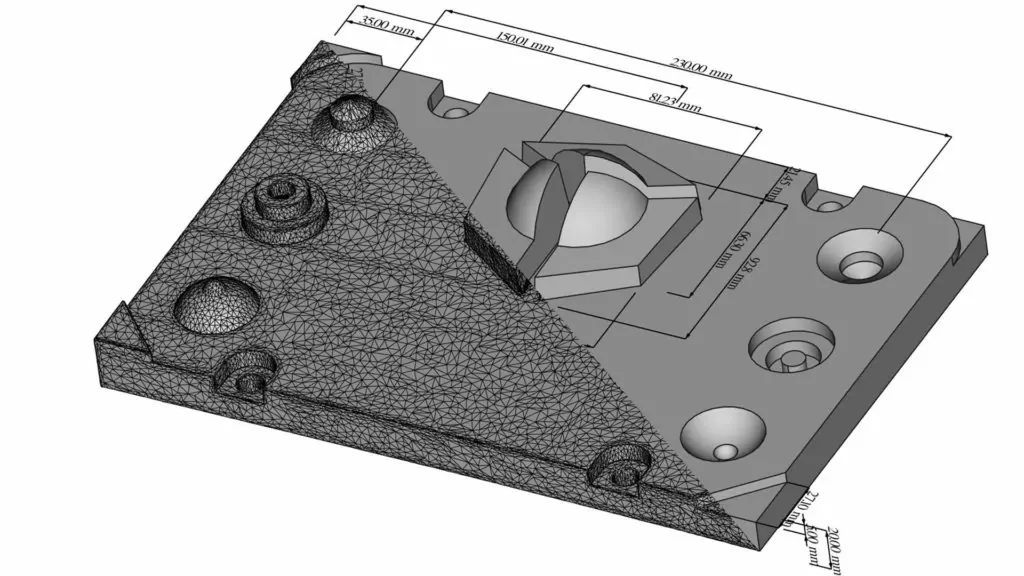

DfAM focuses on designing parts specifically for the additive manufacturing process, considering how a component will be printed layer by layer. Designers must account for factors such as print orientation, layer bonding, support structures, and material behavior during printing. These considerations directly influence part strength, surface quality, dimensional accuracy, and overall performance. Ignoring DfAM principles often results in weak structures, poor surface finishes, or complete print failures.

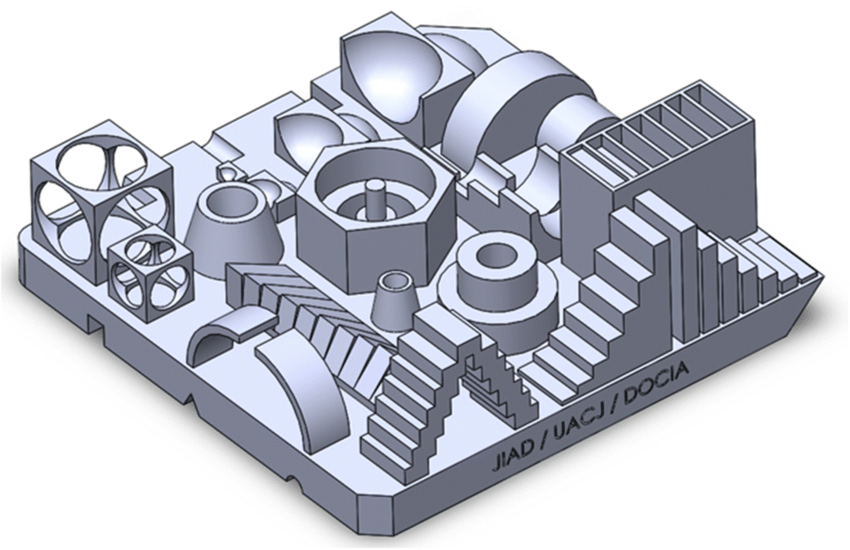

Complex geometry without manufacturing limits

Additive manufacturing enables the creation of complex geometries that are impossible or extremely difficult to produce using traditional machining methods. DfAM fully leverages this design freedom by allowing engineers to create internal channels, lattice structures, and organic shapes without concerns about tool access or machining constraints. This design flexibility enables improved airflow, enhanced cooling performance, and optimized structural efficiency, especially in high-performance and space-constrained components.

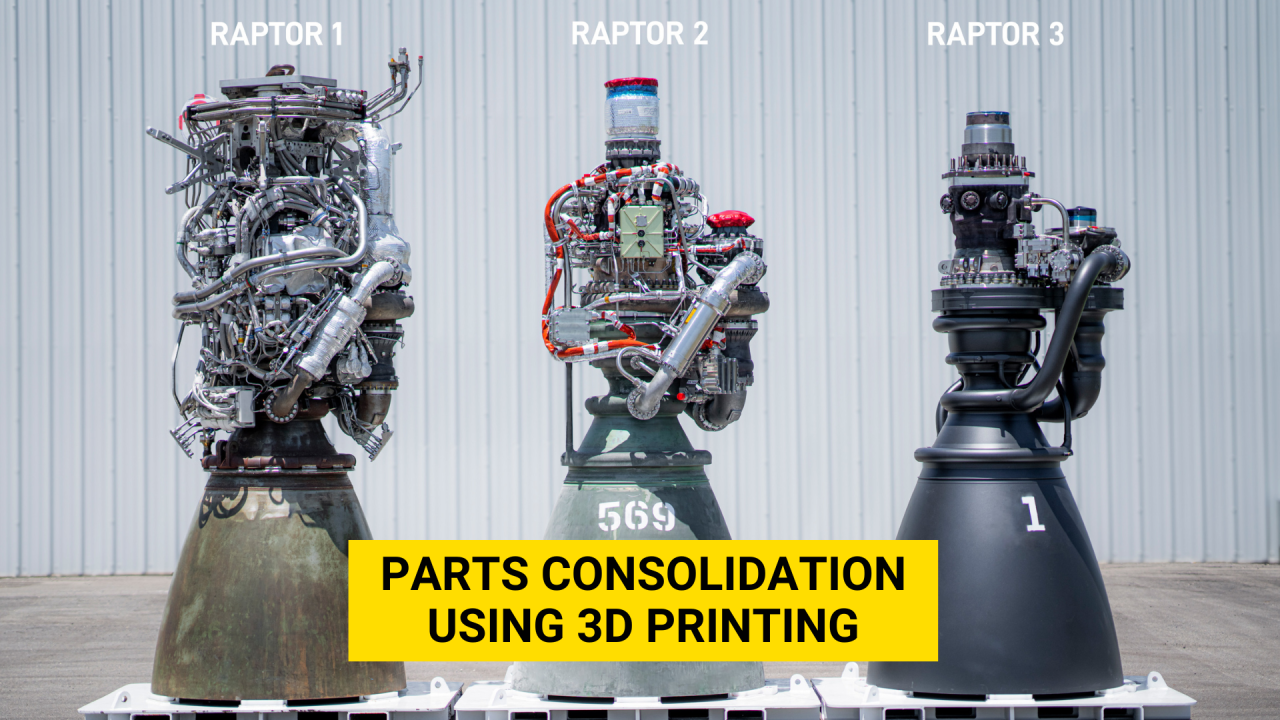

Part consolidation and functional integration

DfAM allows multiple individual components to be combined into a single, fully functional printed part. Features such as fasteners, joints, hinges, and internal passages can often be integrated directly into the design, eliminating the need for secondary assemblies. This significantly reduces assembly time, lowers the number of failure points, and improves overall product reliability. Industries such as aerospace, automotive, and industrial tooling frequently adopt this approach to simplify complex assemblies and improve durability.

Weight reduction and material efficiency

One of the key advantages of DfAM is the ability to place material only where it is structurally required. Engineers can remove unnecessary mass while maintaining strength, stiffness, and load-bearing capability in critical areas. Lightweight designs not only improve performance but also reduce material usage and production costs. This is particularly valuable in aerospace, automotive, and robotics applications, where weight reduction directly impacts efficiency and functionality.

DfAM transforms additive manufacturing from a rapid prototyping method into a production-ready manufacturing process. When design and manufacturing considerations are aligned from the beginning, 3D printing can deliver measurable improvements in performance, efficiency, and cost-effectiveness. DfAM enables organizations to fully unlock the true potential of additive manufacturing.